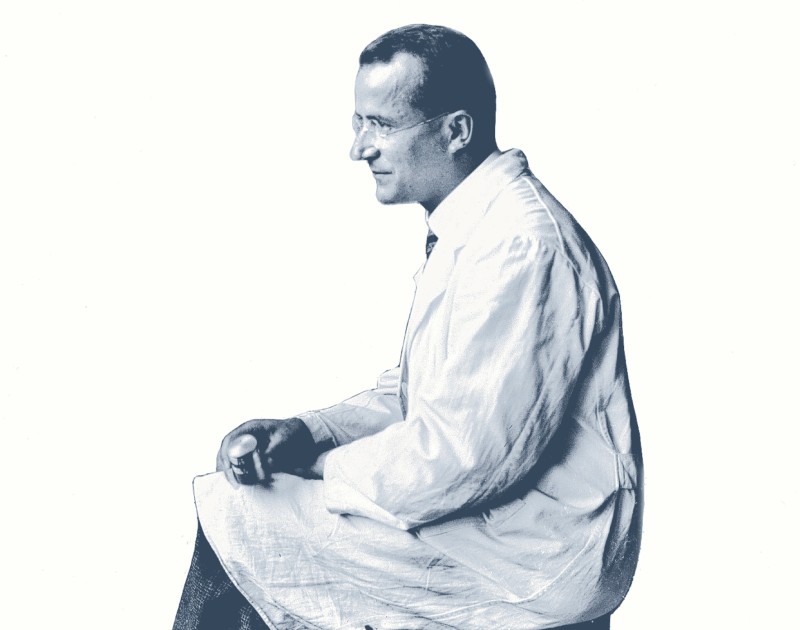

恩斯特·马勒

遇过去,见未来 ——马勒的故事从这里开始

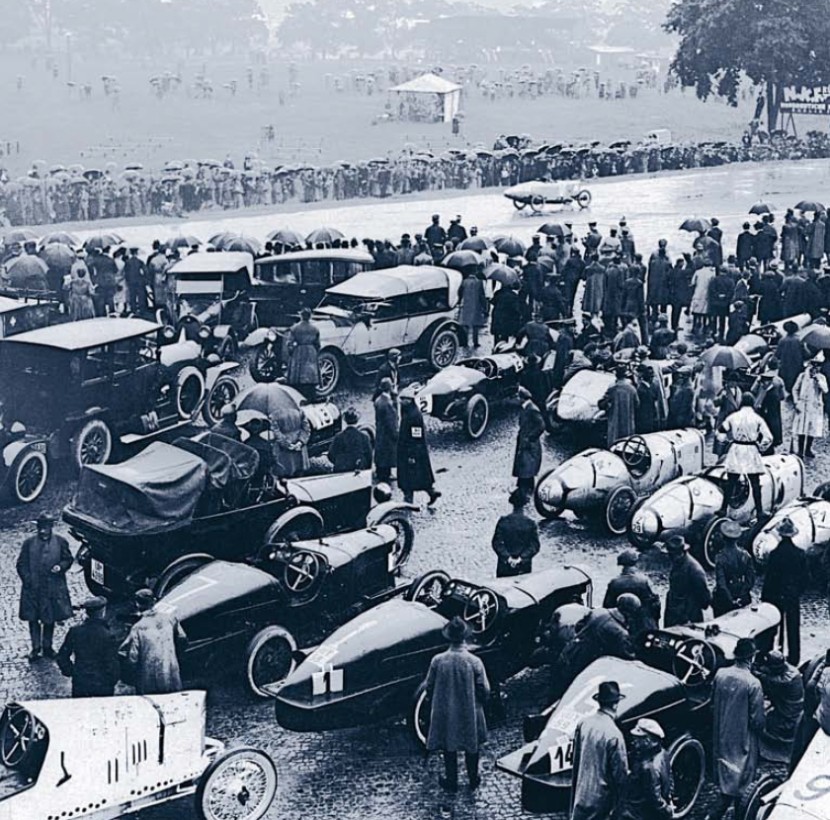

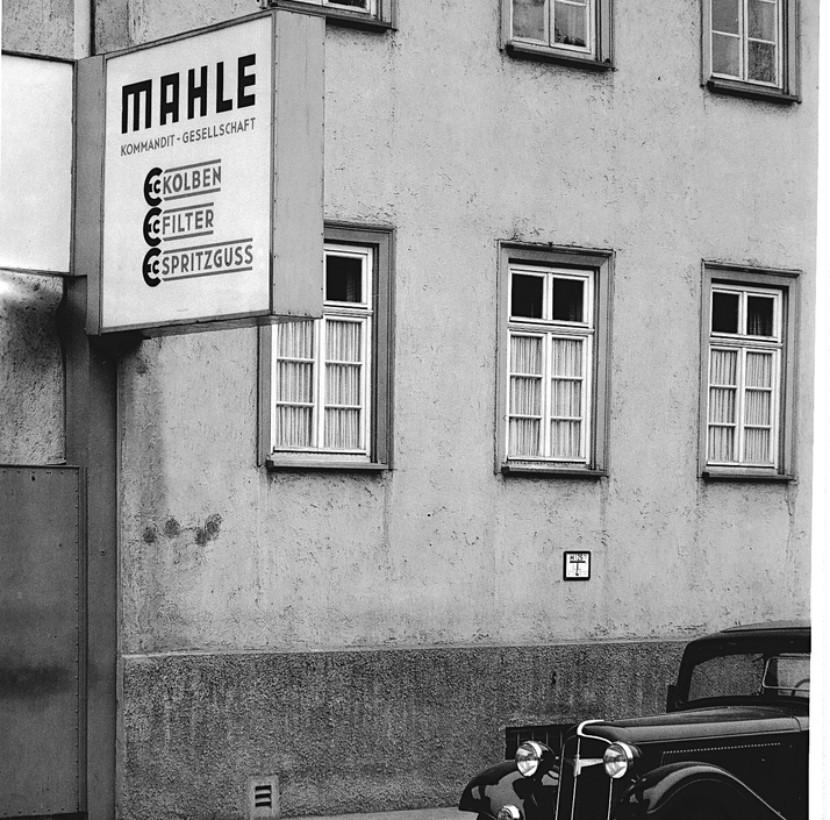

一切都始于1920年时的一个不起眼的维修店铺。今天,大家可能会称其为创业公司。赫尔曼·马勒在那一年加入了Hellmuth Hirth创办的发动机试制工厂,担任商务经理一职。很快他们便决定生产用于发动机的轻合金活塞。1922年,恩斯特·马勒作为开发人员和生产主管加入。然而,技术仍然十分棘手,问题频发。为了防止污垢和灰尘进入发动机,他们开发了空滤和机油滤。在短短几年内,公司便跻身德国主要的活塞制造商之列。两兄弟成为常务董事,最终成为公司唯二的所有者。而他们身上最珍贵的品质便是足智多谋和坚持不懈。

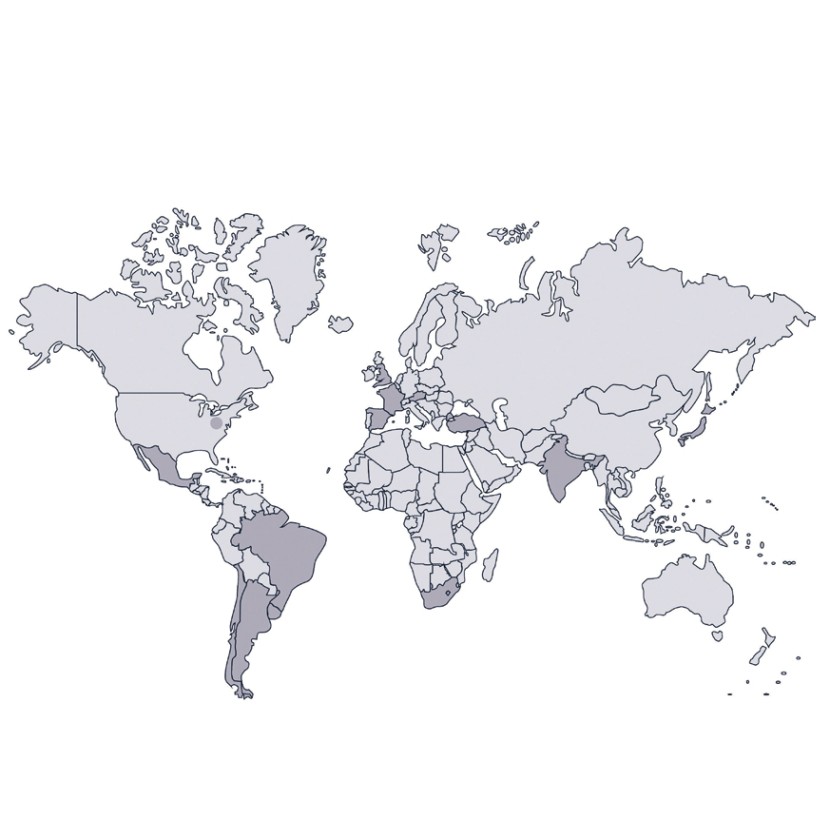

从成立之初直至今日,公司已发展成为汽车行业的全球开发合作伙伴和供应商,也是未来出行的技术驱动者。

| 1920 |

|

| 1922 |

|

| 1924 |

|

| 1926 |

|

| 1927 |

|

| 1930 |

|

| 1931 |

|

| 1933 |

|

| 1935 |

|

| 1937 |

|

| 1938 |

|

| 1940 |

|

| 1943/44 |

|

| 1944 |

|

| 1948 |

|

| 1949 |

|

| 1950 |

|

| 1951 |

|

| 1952 |

|

| 1955 |

|

| 1957 |

|

| 1964 |

|

| 1965 |

|

| 1967 |

|

| 1968 |

|

| 1969 |

|

| 1971 |

|

| 1972 |

|

| 1973 |

|

| 1974 |

|

| 1975 |

|

| 1976 |

|

| 1978 |

|

| 1979 |

|

| 1980 |

|

| 1981 |

|

| 1983 |

|

| 1984 |

|

| 1985 |

|

| 1986 |

|

| 1987 |

|

| 1988 |

|

| 1989 |

|

| 1990 |

|

| 1991 |

|

| 1992 |

|

| 1993 |

|

| 1994 |

|

| 1995 |

|

| 1996 |

|

| 1997 |

|

| 1998 |

|

| 1999 |

|

| 2000 |

|

| 2001 |

|

| 2002 |

|

| 2003 |

|

| 2004 |

|

| 2005 |

|

| 2006 |

|

| 2007 |

|

| 2008 |

|

| 2009 |

|

| 2010 |

|

| 2011 |

|

| 2012 |

|

| 2013 |

|

| 2014 |

|

| 2015 |

|

| 2016 |

|

| 2017 |

|

| 2018 |

|

| 2019 |

|

| 2020 |

|