无可辩驳的事实数据

位于密歇根州的马斯基根工厂

内部发动机测试为产品的功能与质量提供了无可辩驳的事实依据。

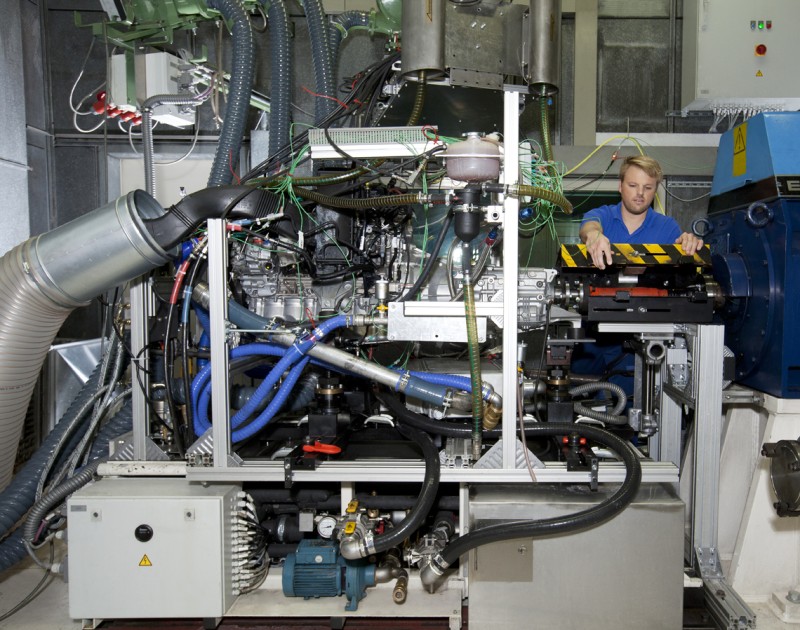

对发动机中的零部件进行测试是发动机研发中不可缺少的一部分。 内部发动机测试可提供产品功能和质量方面的真实情况。

马勒集团拥有13个技术中心、8个发动机测试基地共92个试验台。 这些技术中心以及发动机测试实验室邻近汽车工业最重要的开发中心,可与当地客户进行密切合作。

发动机及其组件的开发和测试越来越分散化。 因此,各个发动机测试地点之间的透明度和交流必不可少。

马勒发动机测试地点通过全球数据库和工作平台进行联网。 这意味着可随时在本地使用技术数据,而且保证了信息和技术的定期交流。 在定期会议中对发动机测试、测量和分析方法的战略以及测试方案进行讨论和比较。

主要任务

马勒发动机测试包括各种任务,这些任务基本上可分为六个领域。

- 开发测量方法

新的测量、测试和分析方法可提供新产品开发方面的重要信息。 在进行全球协调和本地开发之后,马勒集团将新方法在全球范围内推广。 这意味着这些新方法可在所有地点实施,为马勒和客户提供有价值的数据和事实。 - 基础研究

这包括编制并验证与特殊问题和主题领域相关的普遍适用措施的目录。 - 新产品的发动机测试

在将新产品推向客户应用前,它们必须满足高度的技术成熟度和功能性。 因此,我们在发动机测试中对新产品进行内部测试和验证。 - 产品的发动机测试到系列产品发布

在产品开发过程中,对现有产品进行修改,使其适合客户的规格,并在具体客户的发动机测试中进行测试。 功率单元部件(PCU,包括活塞、活塞环和气缸套)的整体测试对于评估各个部件之间的相互作用及彼此协调而言必不可少。 - 故障排除

系列生产产品的复杂性需要迅速的反应。 若出现现场故障,必须在发动机测试设施用适当的测试进行再现,从而可对潜在的补救措施进行测试。 - 开发服务

发动机测试能够基于经验和专业技术为客户提供各种支持,提供各种发动机测试作为开发服务。

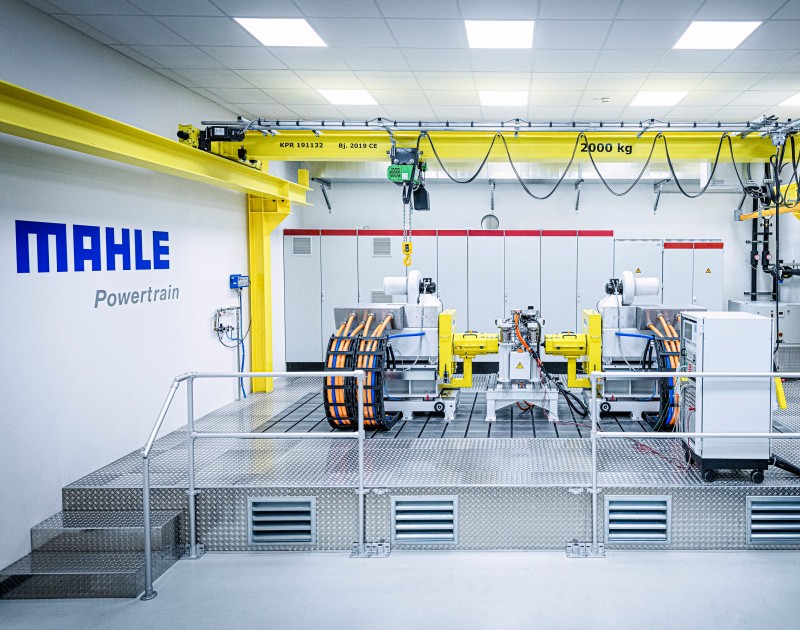

德国费尔巴赫园区的电驱动测试台架

电驱动测试台架

马勒在斯图加特费尔巴赫园区启用了一套高度现代化的电驱动测试台架。该设施将用于各类纯电动和混动车辆的电动轴和电驱动装置的开发和测试。首个客户件测试已于2020年11月成功完成。

投资额达300万欧元的这套测试台架将为客户以及开发人员带来便利。它也是马勒技术转型过程中的又一大里程碑。

燃料电池正在马勒氢能测试中心接受测试

氢能测试中心

马勒在德国斯图加特的全新氢能测试中心投入使用。这里的设施将专门用于燃料电池和几乎零排放的氢燃料发动机的零部件测试,从而帮助汽车行业开发经济而可靠的系统解决方案。在斯图加特,有大约100人规模的团队致力于氢技术相关的项目工作。早在十多年前开始,马勒就已成为燃料电池车辆的供应商。

低温台架

低温台架

低温台架可测试评估发动机的冷启动表现和冷启动磨损对不同表面涂层的影响。包含冷却液、机油和进气在内的整个测试台架最低可降至零下28°C。

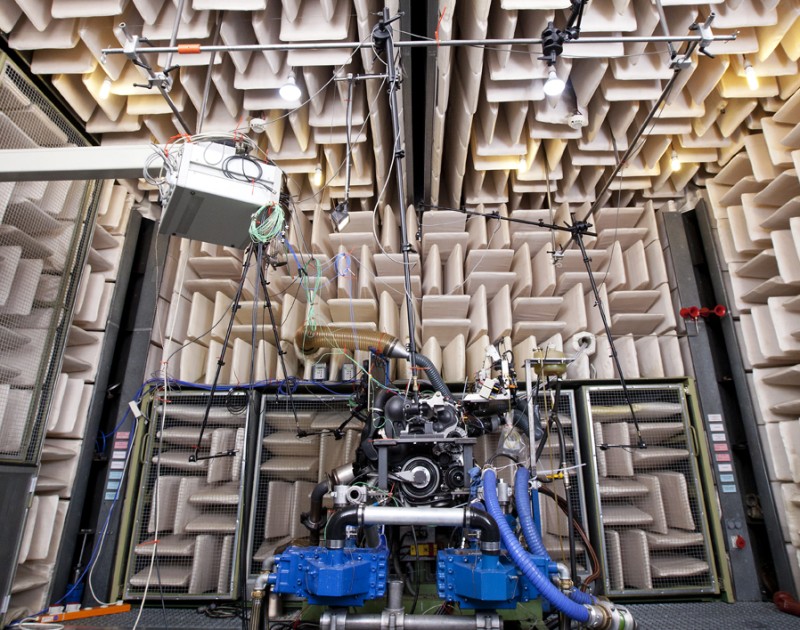

声学测试台架

声学测试台架

低声音反射测试台架用于广泛的NVH表现测试,从而改善活塞、轴瓦、气门组件、进气模块等零部件的声学表现。结构传播和空气传播的噪声都可测量。明确的测试程序能够精确复制噪声,因而能够客观地对比不同的对策。

可测试整台发动机的摩擦力台架